Table of Contents:

- Introduction: The Role of Polyester Filament in Modern Down Jackets

- Essential Performance Requirements for Down Jacket Fabrics

- Key Specifications: Denier, Filament Count, and Fabric Weight

- Fabric Construction: Weaves, Coatings, and Laminates

- Down-Proofness Standards and Testing Methods

- Water Resistance and Breathability Requirements

- Durability and Abrasion Resistance Standards

- Color Fastness and Appearance Retention

- Environmental and Sustainability Considerations

- Cost Analysis and Market Price Ranges

- Industry Standards and Compliance Requirements

- Frequently Asked Questions (FAQs)

The Comprehensive Guide to Polyester Filament Fabrics for Down Jackets: Specifications, Performance, and Selection Criteria .What are the specifications of polyester filament fabrics for down jackets?

1. Introduction: The Role of Polyester Filament in Modern Down Jackets

Polyester filament fabrics have become the industry standard for premium down jackets, offering an optimal balance of performance, durability, and cost-effectiveness. These engineered textiles provide the essential barrier that contains down clusters while protecting against external elements. For procurement professionals and manufacturers, understanding the precise specifications of these fabrics is crucial for product development, quality control, and competitive positioning in the global outerwear market.

The down jacket sector represents approximately 35% of the global technical outerwear market, valued at $28.3 billion in 2024, with polyester filament fabrics accounting for over 70% of shell materials. This dominance is driven by continuous innovation in fiber engineering, fabric construction, and finishing technologies that address the unique challenges of down containment and weather protection.

2. Essential Performance Requirements for Down Jacket Fabrics

Down jacket fabrics must simultaneously address multiple performance demands:

- Down-Proofness: Preventing feather penetration while maintaining breathability

- Weather Resistance: Water repellency, wind resistance, and UV protection

- Durability: Withstanding abrasion, tearing, and repeated compression

- Weight Efficiency: Maximizing warmth-to-weight ratio

- Comfort: Flexibility, drape, and next-to-skin feel in collar and cuff areas

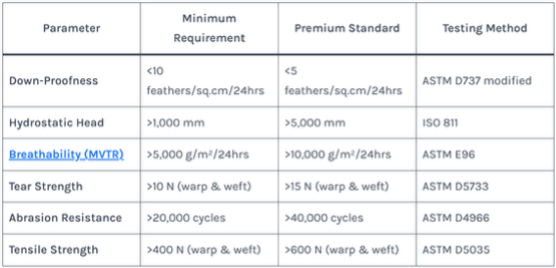

Table 1: Critical Performance Parameters for Down Jacket Fabrics

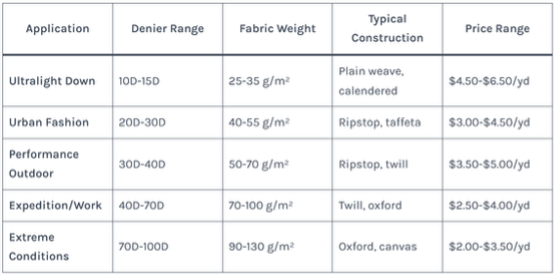

3. Key Specifications: Denier, Filament Count, and Fabric Weight

Denier Selection:

- 10D-20D: Ultra-lightweight for premium down garments, offering maximum packability

- 20D-40D: Standard range for most down jackets, balancing weight and durability

- 40D-70D: Heavy-duty applications, expedition gear, and workwear

- 70D+: Specialized applications requiring extreme durability

Filament Configuration:

- Microfiber (<1 DPF): Enhanced down-proofness and soft hand feel

- Fine filament (1-2 DPF): Optimal balance of performance and cost

- Standard filament (>2 DPF): Maximum durability for high-stress areas

Fabric Weight Ranges:

- Ultra-light: 25-40 g/m² (10-20D constructions)

- Lightweight: 40-60 g/m² (20-40D constructions)

- Medium-weight: 60-90 g/m² (40-70D constructions)

- Heavy-duty: 90-130 g/m² (70D+ constructions)

Table 2: Fabric Specification Matrix by Application

4. Fabric Construction: Weaves, Coatings, and Laminates

Weave Types:

- Plain Weave: Basic construction, good down-proofness, moderate strength

- Twill Weave: Enhanced durability, better drape, slightly reduced down-proofness

- Ripstop: Grid reinforcement for tear resistance, signature outdoor aesthetic

- Oxford: Heavy-duty construction, maximum durability

Down-Proof Weave Technologies:

- High-density plain weaves: 280-400 threads/inch

- Micro-ripstop patterns: 5×5 to 10×10 mm grids

- Tight taffeta constructions: 190T-300T thread counts

Surface Treatments:

- DWR (Durable Water Repellent): C6/C8 fluorocarbon or newer C0 alternatives

- Calendering: Heat and pressure treatment for enhanced down-proofness

- Softening treatments: Silicone or polyurethane-based finishes for improved hand feel

Laminates and Membranes:

- 2-layer: Fabric + membrane (e.g., GORE-TEX, eVent)

- 2.5-layer: Ultra-lightweight with printed membrane

- 3-layer: Fabric + membrane + lining for maximum durability

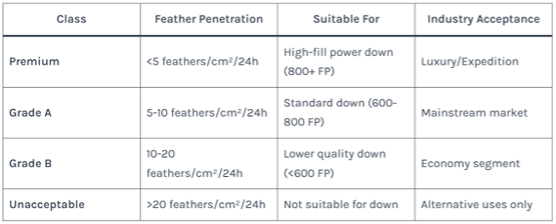

5. Down-Proofness Standards and Testing Methods

Industry Standards:

- EN 1162: European standard for down and feather penetration

- ISO 811: Modified for down-proofness testing

- Brand-specific standards: Patagonia, The North Face, Arc’teryx proprietary tests

Testing Methodology:

- Sample preparation: 100 cm² fabric samples

- Test apparatus: Down-proofness tester with regulated pressure

- Test duration: 24 hours minimum

- Measurement: Feather count through fabric under microscope

- Classification: Based on feathers per square centimeter

Table 3: Down-Proofness Classification System

6. Water Resistance and Breathability Requirements

Water Resistance Standards:

- Light rain protection: 1,000-3,000 mm hydrostatic head

- Heavy rain protection: 3,000-5,000 mm hydrostatic head

- Storm protection: 5,000-10,000 mm hydrostatic head

- Extreme conditions: 10,000+ mm hydrostatic head

Breathability Metrics:

- Minimum comfort: 5,000 g/m²/24h MVTR

- Active wear: 10,000-15,000 g/m²/24h MVTR

- High exertion: 15,000-20,000 g/m²/24h MVTR

- Maximum breathability: 20,000+ g/m²/24h MVTR

Table 4: Water Resistance vs. Breathability Balance

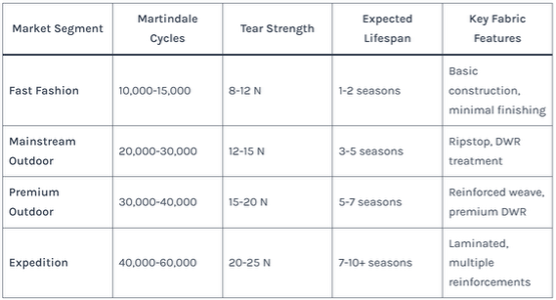

7. Durability and Abrasion Resistance Standards

Abrasion Resistance:

- Martindale test: Standard method for abrasion resistance

- Taber test: Alternative method for heavier fabrics

- Field testing: Actual wear testing over 6-12 month periods

Durability Factors:

- Yarn tenacity: Minimum 4.5 g/denier for down jacket applications

- Fabric construction: Thread count and weave density

- Finishing treatments: Anti-abrasion coatings and treatments

Table 5: Durability Specifications by Market Segment

8. Color Fastness and Appearance Retention

Color Fastness Requirements:

- Wash fastness: ISO 105-C06 minimum Grade 4

- Light fastness: ISO 105-B02 minimum Grade 5

- Rub fastness: ISO 105-X12 minimum Grade 4 dry, 3-4 wet

- Sublimation fastness: Minimum Grade 4 at 180°C

Appearance Retention:

- Pilling resistance: ASTM D4970 minimum Grade 3.5

- Wrinkle recovery: AATCC 128 minimum 70% recovery

- Dimensional stability: ISO 5077 maximum 3% shrinkage

Special Considerations for Down Jackets:

- Down oil resistance: Color must not be affected by natural down oils

- Cleaning compatibility: Must withstand professional down cleaning processes

- UV degradation: Critical for jackets used in high-altitude environments

9. Environmental and Sustainability Considerations

Sustainable Material Options:

- Recycled polyester: rPET content from 50-100%

- Bio-based polymers: Partially renewable content alternatives

- PFC-free DWR: C0 technology alternatives to fluorocarbons

Environmental Certifications:

- bluesign® approved: Comprehensive environmental standard

- OEKO-TEX Standard 100: Chemical safety certification

- GRS (Global Recycled Standard): Recycled content verification

- RDS (Responsible Down Standard): Ethical down sourcing

Carbon Footprint Comparison:

- Virgin polyester: 5.5 kg CO₂e/kg fiber

- Recycled polyester: 3.2 kg CO₂e/kg fiber (42% reduction)

- Industry target: 2.0 kg CO₂e/kg fiber by 2030

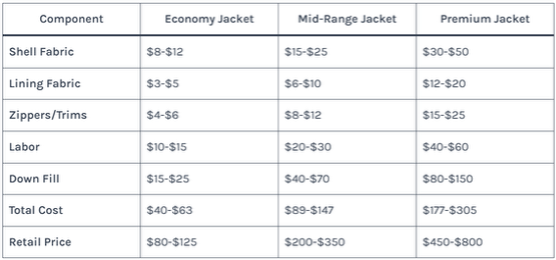

10. Cost Analysis and Market Price Ranges

Cost Components:

- Raw materials: 45-60% of total fabric cost

- Weaving/knitting: 20-30%

- Finishing/treatment: 15-25%

- Quality control/testing: 5-10%

Market Price Ranges (2024):

- Economy fabrics: $1.50-$2.50/yard (40D-70D, basic finishes)

- Mid-range fabrics: $2.50-$4.50/yard (20D-40D, DWR treated)

- Premium fabrics: $4.50-$7.50/yard (10D-30D, laminated, recycled)

- Specialty fabrics: $7.50-$15.00/yard (ultralight, technical features)

Table 6: Total Cost Analysis for Typical Down Jacket

11. Industry Standards and Compliance Requirements

Global Standards:

- ISO 3758: Care labeling requirements

- ISO 13934: Tensile strength testing

- ISO 13937: Tear strength testing

- ASTM F2732: Performance specification for down products

Regional Compliance:

- EU: REACH, Textile Labeling Regulation

- USA: CPSIA, FTC Care Labeling Rule

- Canada: Textile Labeling Act

- Japan: Household Goods Quality Labeling Law

Brand-Specific Requirements:

- Fill power verification: Independent testing requirements

- Ethical sourcing: Down traceability systems

- Environmental claims: Verification of recycled content

- Performance claims: Third-party testing validation

12. Frequently Asked Questions (FAQs)

Q1: What is the optimal denier range for down jacket fabrics?

A: For most applications, 20D-40D offers the best balance of weight, durability, and down-proofness. Ultra-lightweight jackets use 10D-20D, while expedition gear uses 40D-70D. The choice depends on intended use, fill power, and price point.

Q2: How does filament count affect down-proofness?

A: Higher filament counts (finer filaments) generally improve down-proofness by creating denser fabric structures. Microfiber constructions (<1 DPF) offer the best down containment but may require special weaving techniques to maintain durability.

Q3: What hydrostatic head rating is necessary for down jackets?

A: For general use, 3,000-5,000 mm provides adequate protection. For serious outdoor use in wet conditions, 5,000-8,000 mm is recommended. Ultra-lightweight jackets may have 1,000-2,000 mm, prioritizing breathability over waterproofing.

Q4: How important is breathability in down jacket fabrics?

A: Critical. Down loses insulation value when damp from perspiration. Minimum 5,000 g/m²/24h MVTR is essential, with 10,000+ preferred for active use. However, there’s always a trade-off between breathability and water resistance.

Q5: Can recycled polyester meet down jacket performance requirements?

A: Yes. Modern recycled polyester achieves comparable performance to virgin polyester in down-proofness, durability, and water resistance. Premium brands now commonly use 100% recycled shell fabrics without performance compromise.

Q6: What is the industry standard for down-proofness testing?

A: The modified ASTM D737 method measuring feather penetration over 24 hours is most common. Premium fabrics must allow fewer than 5 feathers/cm², while commercial grades permit up to 10 feathers/cm².

Q7: How do coatings and laminations affect fabric specifications?

A: Coatings improve water resistance but may reduce breathability. Laminates (like GORE-TEX) create a balance but add weight and cost. Uncoated fabrics offer maximum breathability but require higher thread counts for down-proofness.

Q8: What are the care requirements for down jacket fabrics?

A: Most require gentle machine washing with down-specific detergent, tumble drying on low with tennis balls to restore loft. DWR treatments may require periodic renewal. Professional cleaning is recommended for laminated fabrics.

Q9: How does fabric weight correlate with warmth?

A: Fabric weight itself doesn’t determine warmth—down fill weight and fill power do. However, lighter fabrics allow more down to be used within overall weight limits, potentially increasing warmth. Heavier fabrics offer durability advantages.

Q10: What sustainability certifications should buyers look for?

A: Key certifications include bluesign® for environmental manufacturing, OEKO-TEX for chemical safety, GRS for recycled content, and RDS for ethical down sourcing. The combination of these indicates comprehensive sustainability commitment.